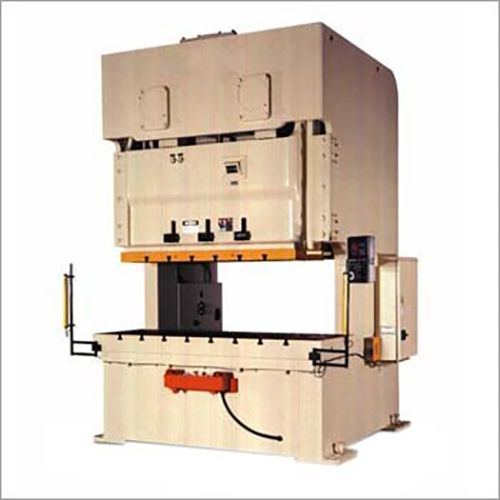

Pointing Power Press Machine

Product Details:

- Product Type Power Press Machine

- Application Industrial

- Warranty 1 Year

- Click to View more

Pointing Power Press Machine Price And Quantity

- 500000 INR/Piece

- 1 Piece

Pointing Power Press Machine Product Specifications

- Power Press Machine

- Industrial

- 1 Year

Pointing Power Press Machine Trade Information

- 1 Piece Per Month

- 2 Months

- loss packing

- Eastern Europe, Australia, Middle East, Western Europe, Africa, Central America, South America, Asia, North America

- All India

- ISO:9001 , 2008

Product Description

With the assistance of our team of professionals, we are engaged in providing an assorted range of Single Point Power Press Machine. The offered machine is used in the various industries for bending the workpiece by applying hydraulic, pneumatic force. This machine is manufactured by our technical professionals using premium grade raw material and latest techniques to meet the set quality standards. Offered Single Point Power Press Machine is available for our clients in various technical specifications at affordable rates.

Features:

- Rugged design

- High operational fluency

- Unmatched performance

- Durability

Technical Specification:

| Item Model-BMT |

10 |

16 |

25 |

40 |

63 |

100 |

160 |

200 |

250 |

||||||||||||||||||||||

| A |

B |

C |

D |

A |

B |

C |

D |

A |

C |

C |

D |

A |

B |

C |

D |

A |

B |

C |

D |

A |

B |

C |

D |

A |

B |

A |

B |

A |

B |

||

| Force (kN) | 100 |

160 |

250 |

400 |

630 |

1000 |

1600 |

2000 |

2500 |

||||||||||||||||||||||

| Rated distance before B.D.C (mm) | 2 |

1.6 |

3.15 |

3 |

3.5 |

2.2 |

4 |

2.2 |

5 |

2.5 |

5 |

2.5 |

6.3 |

6.3 7 |

6.3 8 |

||||||||||||||||

| Stroke Length (mm) | 50 |

8-50 |

50 |

8-50 |

63 |

8-63 |

63 |

8-63 |

80 |

8-80 |

80 |

8-80 |

88 |

8-88 |

88 |

8-88 |

100 |

8-100 |

100 |

8-100 |

125 |

8-125 |

125 |

8-125 |

160 |

50-160 |

200 |

20-160 |

200 |

20-160 |

|

| Number of slide strokes (min-1) | 75 |

150 |

75 |

150 |

70 |

140 |

65 |

130 |

60 |

120 |

45 |

100 |

40 |

40 |

35 |

||||||||||||||||

| Fly wheel energy (kj) | 1.0 |

0.7 |

2.5 |

1.5 |

4.4 |

3.0 |

8.0 |

4.6 |

16.75 |

7.78 |

25.0 |

12.5 |

55.0 |

70.0 |

80.0 |

||||||||||||||||

| Throat depth (mm) | 165 |

185 |

210 |

235 |

285 |

325 |

385 |

410 |

410 |

||||||||||||||||||||||

| Shut height over bed stroke down, Adj Up (mm) | 200 |

265 |

315 |

350 |

400 |

500 |

560 |

560 |

560 |

||||||||||||||||||||||

| Slide adjustment (mm) | 50 |

50 |

63 |

70 |

70 |

80 |

125 |

125 |

125 |

||||||||||||||||||||||

| Slide area (L-R x F-B) (mm) | 255 x 160 |

280 x 170 |

350 x 250 |

400 x 350 |

500 x 400 |

600 x 450 |

800 x 650 |

900 x 800 |

950 x 800 |

||||||||||||||||||||||

| Boister area (L-R x F-B) (mm) | 540 x 315 |

600 x 355 |

630 x 400 |

800 x 450 |

900 x 550 |

1000 x 630 |

1120 x 750 |

1250 x 800 |

1250 x 800 |

||||||||||||||||||||||

| Boister Thickness (mm) | 65 |

70 |

75 |

75 |

90 |

90 |

120 |

150 |

150 |

||||||||||||||||||||||

| Bed opening (L-R x F-B) (mm) | 220 x 160 |

218 x 200 |

315 x 224 |

355 x 250 |

400 x 280 |

500 x 355 |

560 x 450 |

630 x 450 |

630 x 500 |

||||||||||||||||||||||

| Clear distance between uprights (mm) | 330 |

375 |

420 |

500 |

590 |

670 |

775 |

900 |

---- |

||||||||||||||||||||||

| Main motor (kW/rpm) | 1.1 x 1500 |

1.1 x 1000 |

1.5 x 1500 |

1.5 x 1000 |

2.2 x 1500 |

2.2 x 1000 |

3.7 x 1500 |

3.7 x 1000 |

5.5 x 1500 |

5.5 x 1000 |

7.5 x 1500 |

7.5 x 1000 |

15 x 1500 |

15 x 1500 |

18.5 x 1500 |

||||||||||||||||

| Slide adjustment motor (kW/rpm) | ----- |

----- |

----- |

----- |

----- |

----- |

----- |

----- |

----- |

---- |

----- |

----- |

1.1 x 1500 |

1.1 x 1500 |

2.2 x 1500 |

||||||||||||||||

| Height from floor to top of boister (mm) | 800 |

800 |

800 |

900 |

900 |

900 |

900 |

900 |

900 |

||||||||||||||||||||||

| Machine weight (Appx.) kg | 1250 |

1000 |

2000 |

1850 |

2500 |

2500 |

3800 |

3600 |

6000 |

5600 |

9000 |

8500 |

1500 |

20000 |

28000 |

||||||||||||||||

| Required Air Pressure (ATM) | 5.5 |

5.5 |

5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | ||||||||||||||||||||||

DIE CUSHION |

Model --- | ----- |

----- |

DC-82 | DDC-82 | DDC-102 | DDC-123 | 3DC-144 | 3DC-144 | 3DC-164 | |||||||||||||||||||||

| Force (kN) | ----- |

----- |

17 |

44 |

70 |

100 |

200 |

200 |

270 |

||||||||||||||||||||||

| Stroke Length (mm) | ----- |

----- |

50 |

50 |

50 |

75 |

100 |

100 |

100 |

||||||||||||||||||||||

| Pressure pad area (mm) | ----- |

----- |

290 x 200 |

335 x 230 |

380 x 2.60 |

475 x 330 |

535 x 425 |

600 x 425 |

600 x 475 |

||||||||||||||||||||||

| Required Air Pressure (atm) |

----- |

----- |

5.5 |

7 |

7 |

7 |

7 |

7 |

7 |

||||||||||||||||||||||

Standard Accessories:

-

Electric Motor

-

Electrical Control Panel with Controls

-

Stroke Counter

-

Standard Bolster

-

Automatic Centralise Lubrication Device

-

Rototary Com Limit Switch

-

Shear Plate Overhead Safty Device

-

Pneumatic Die cushion for drawing operation

-

Die area light

-

Impulsive stroke counter

-

Roll feed single or double

-

Strip straightner

-

Gripper feed

-

Operator's safety guard

-

Decoilers

-

Hydraulic overload safety device

-

Real stand

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+